- Investigation of Tensile Behaviors in Open Hole and Bolt Joint Configurations of Carbon Fiber/Epoxy Composites

Dong-Wook Hwang*1, Sanjay Kumar*1, Dong-Hun Ha*, Su-Min Jo*, Yun-Hae Kim*†

* Dept. of Ocean Advanced Materials Convergence Engineering, Korea Maritime and Ocean University, Busan 49112, Korea

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study investigated the open hole tensile (OHT) properties of carbon fiber/epoxy composites and compared them to bolt joint tensile (BJT) properties. The net nominal modulus and strength (1376 MPa) were found to be higher than the gross nominal strength (1041 MPa), likely due to increasing hole size. The OHT and BJT specimens exhibited similar stiffness, as expected without bolt rotation causing secondary bending. OHT specimens experienced a sharp drop in stress indicating unstable crack propagation, delamination, and catastrophic failure. BJT specimens failed through shear out on the bolt side and bearing failure on the nut side, involving fiber kinking, matrix splitting, and delamination, resulting in lower strength compared to OHT specimens. The strength retention of carbon fiber/epoxy composites with open holes was 66%. Delamination initiation at the hole's edge caused a reduction in the stress concentration factor. Filling the hole with a bolt suppressed this relieving mechanism, leading to lower strength in BJT specimens compared to OHT specimens. Bolt joint efficiency was calculated as 15%. The reduction in strength in bolted joints was attributed to fiber-matrix splitting and delamination, aligning with Hart Smith's bolted joint efficiency diagram. These findings contribute to materials selection and structural reliability estimation for carbon fiber/epoxy composites. They highlight the behavior of open hole and bolt joint configurations under tensile loading, providing valuable insights for engineering applications.

Keywords: Carbon fiber/epoxy composites, Open hole and bolt joint tensile properties, Bolt joint efficiency, Damage behavior

Composite materials are widely recognized for their exceptional strength-to-weight ratio and stiffness-to-weight ratio, offering distinct advantages over conventional metals [1-4]. As a result, composite materials have become the preferred choice in numerous industrial and research sectors [5-7]. In recent times, fiber-reinforced polymer composites have witnessed extensive usage, particularly in the construction of automobile and aircraft structures. The vulnerability of composite structures primarily lies in their mechanical connections. Conventional static tests indicate that an aluminum alloy-based mechanical joint significantly surpasses a fiber reinforced polymer (FRP), designed as its replacement for structural purposes, in terms of strength retention. Nevertheless, these assessments have not hindered the continued prosperity of fiber reinforced polymer (FRP) over their metal alloy counterparts in the field of aeronautics. This achievement can be primarily attributed to the proven long-term mechanical performance, equalizing weight considerations [8], and the advantage of fewer assembly components [5], leading to reduced final expenses. The available literature suggests that the extensive exploration of open composites can be attributed to the ease with which experimental testing and analysis can be conducted. Nonetheless, in real-world scenarios, the fastening of aircraft components is primarily accomplished through the use of bolts. Open-hole tensile (OHT) [9] and single-lap bolted joint (BJ) tests serve as fundamental methods to obtain the necessary mechanical characteristics for analytical modelling [10,11]. In the aerospace industry, for instance, the ASTM standards for Open-hole tensile (OHT) and single-lap bolted joint (BJ) tests and practice [12,13] are widely employed to generate data for fastened parts. This investigation focuses on exploring the tensile behavior of Open-hole tensile (OHT) and single-lap bolted joint (BJ), with the aim of providing additional insights to enhance future analytical modelling of composites.

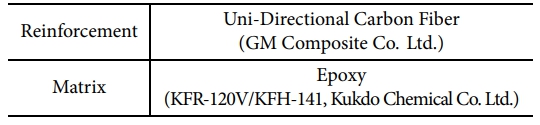

2.1 Materials and Specimen Preparation

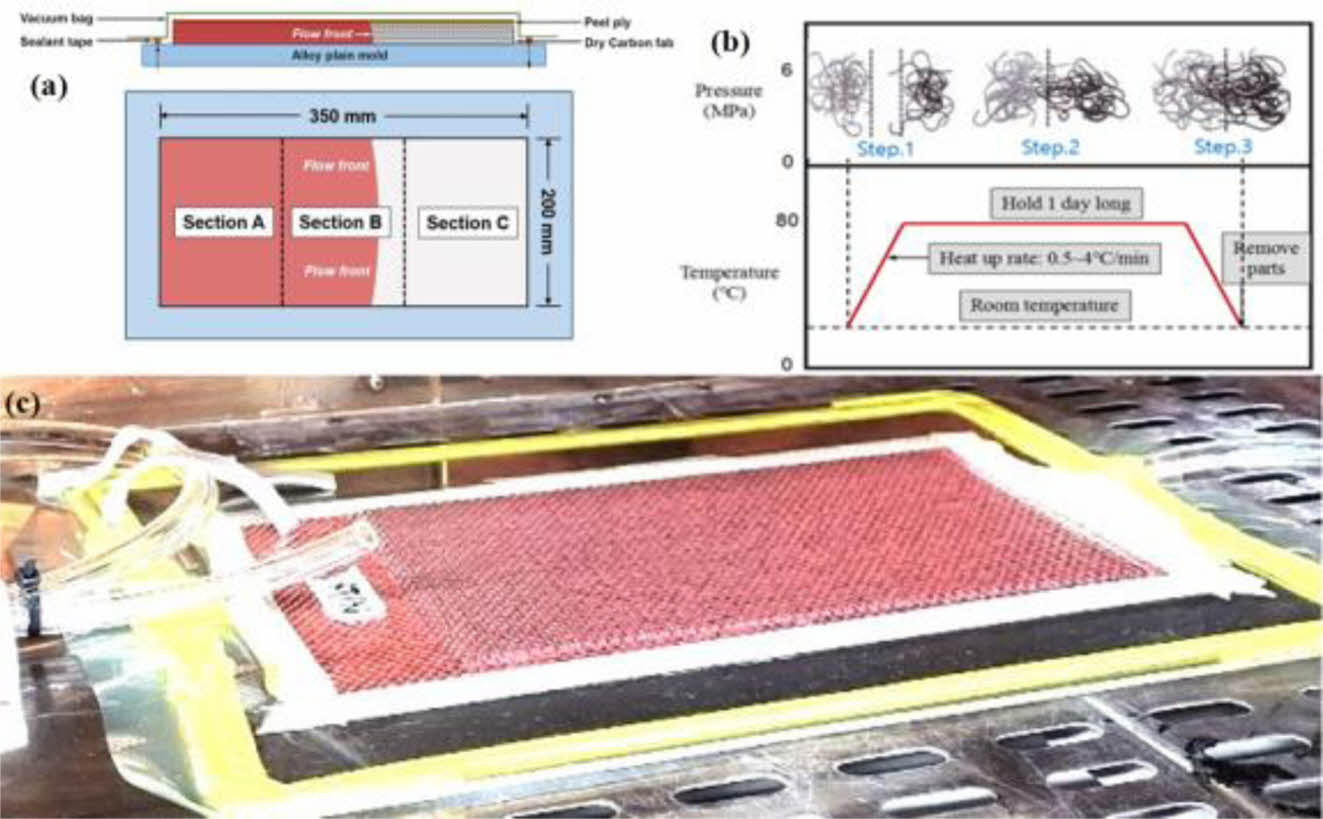

Unidirectional carbon fabric sourced from GM COMPOSITE CO., LTD was utilized as the reinforcement material. The matrix consisted of epoxy resin (KFR-120V, KUKDO chemical CO., LTD) And curing agent (KFH-141, KUKDO chemical CO., LTD) in a weight ratio of 100:30. The VaRTM was employed to create the sample, as illustrated in Fig. 1. Fig. 1a shows the processing of VaRTM. The processing parameters of the VaRTM is shown in Fig. 1b and experimental representation composites processing is shown in Fig. 1c.

2.2 Mechanical Tests

Open hole tensile tests on composites were conducted using a universal testing machine (KDMT-100 KN Korea) equipped with a 100 kN load cell at room temperature, following the guidelines outlined in the ASTM D5766 standard. The specimens had dimensions of 250 mm × 25 mm × 3 mm. To create the open holes at the center of the specimens, an aluminum end tab was attached, and a drilling machine was employed. Modified hollow cylindrical steel drilling bits were used to meticulously form circular holes through the specimen's core. The circular hole was initially established by drilling a small starter hole and progressively enlarged through incremental drilling to achieve the final dimensions. To ensure a clean and smooth hole while preventing delamination at the hole's edge, a flat wooden plate was placed beneath the specimen and securely clamped. The notched region was meticulously hand-polished using sandpaper. The single-lap bolted joint (BJ) tests were performed according to ASTM-D5961. The five tests were conducted for each specimen.

|

Fig. 1 a) Flow section of VaRTM, b) curing cycle of VaRTM, and c) experimental representation composites processing |

3.1 Open Hole Tensile (OHT) Properties of the

CF/epoxy

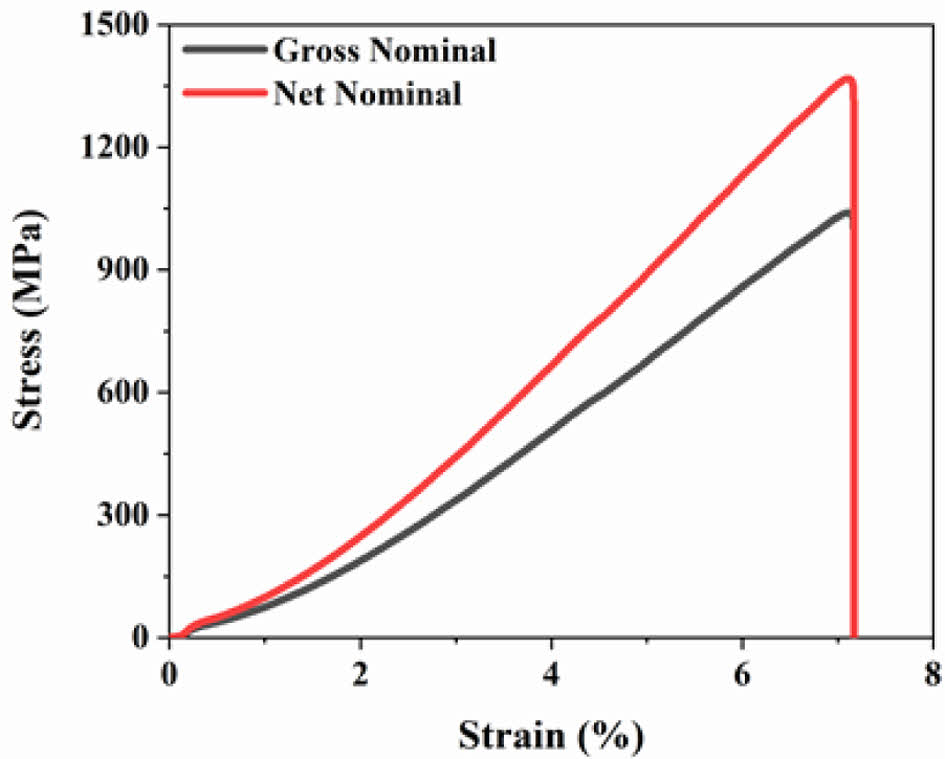

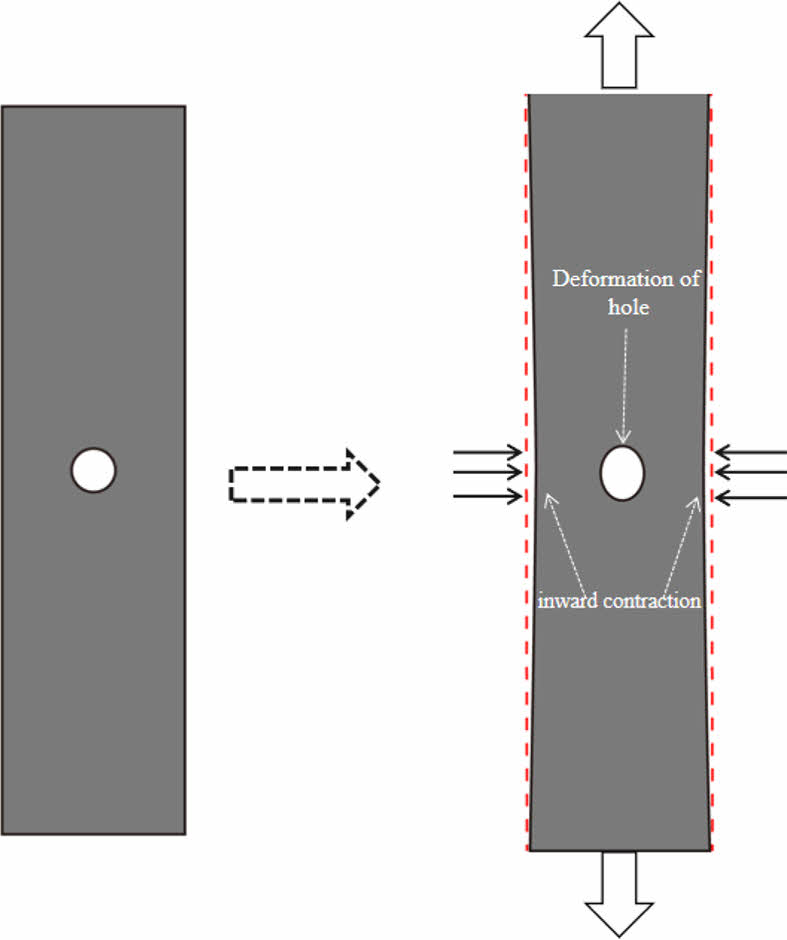

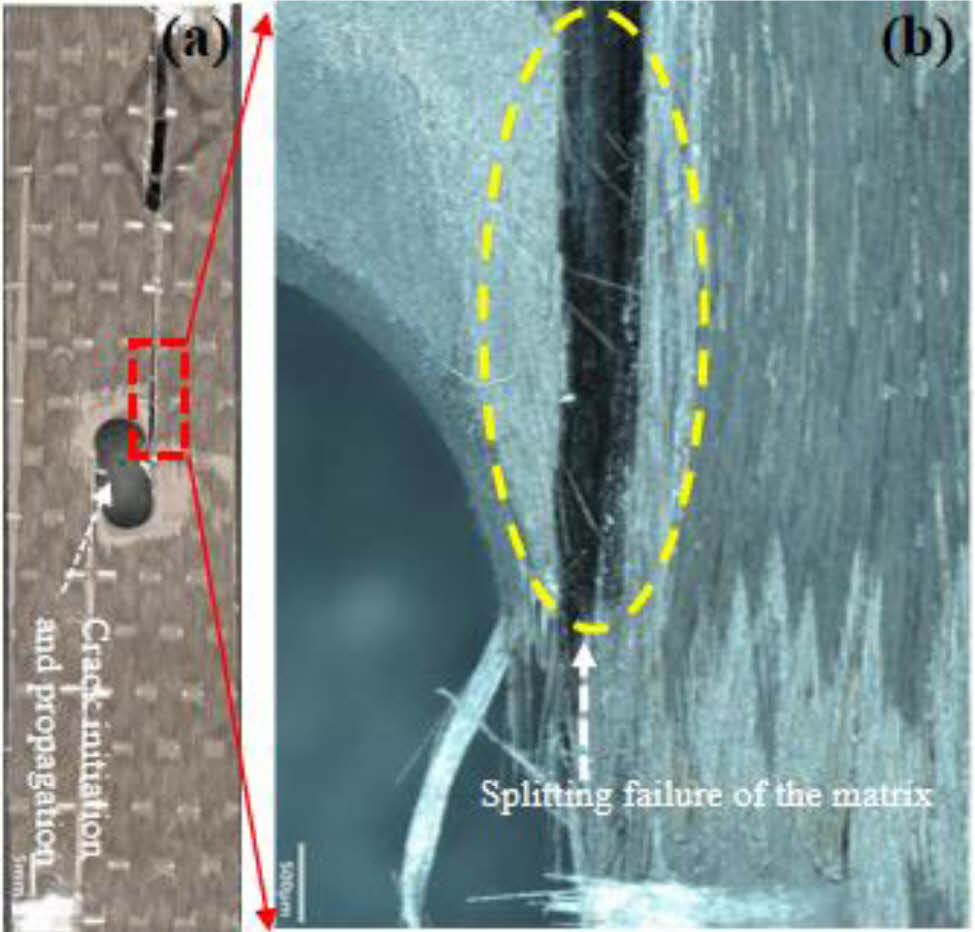

The open hole strength data may be useful for both materials selection and for estimation of structural reliability. To elucidate the effect of stress concentration on the tensile strength of composites with open circular holes were tested with tension. The typical gross nominal and net nominal stress-strain curves of composites are shown in Fig. 2. The gross nominal stress-strain curves of the open hole specimens followed the curve path of the net nominal stress-strain curves up to certain strain values after that started to divert. This may be because of increasing hole size (as shown in the Fig. 4a), caused to get the higher net nominal modulus and strength (1376 MPa) than that of the gross nominal (strength = 1041 MPa). The phenomenon of stiffening arises as a consequence of the reduced cross-sectional area in specimens containing open holes. Under loading conditions, the presence of these holes induces lateral deformation in the two ligaments. In such instances, the inward contraction acts as a restraining load against longitudinal deformation as shown in the Fig. 3. As a result, the affected region surrounding the hole exhibits a diminished magnitude of longitudinal deformation. This stiffening phenomenon has been observed by previous researchers [7,9,17,18]. Their studies have revealed that varying the size of the hole prior to final failure leads to an increased modulus and strength (specifically, the net nominal modulus and strength) compared to the gross nominal modulus and strength. The failure in the open hole specimens started from hole edge perpendicular to application of the load (as it marked in the specimens Fig. 4a). It results in the splitting failure of the matrix initiated at the hole edge and hole grew in size with increasing load up to the final fracture of the fiber (as shown in the Fig. 4b) and specimens.

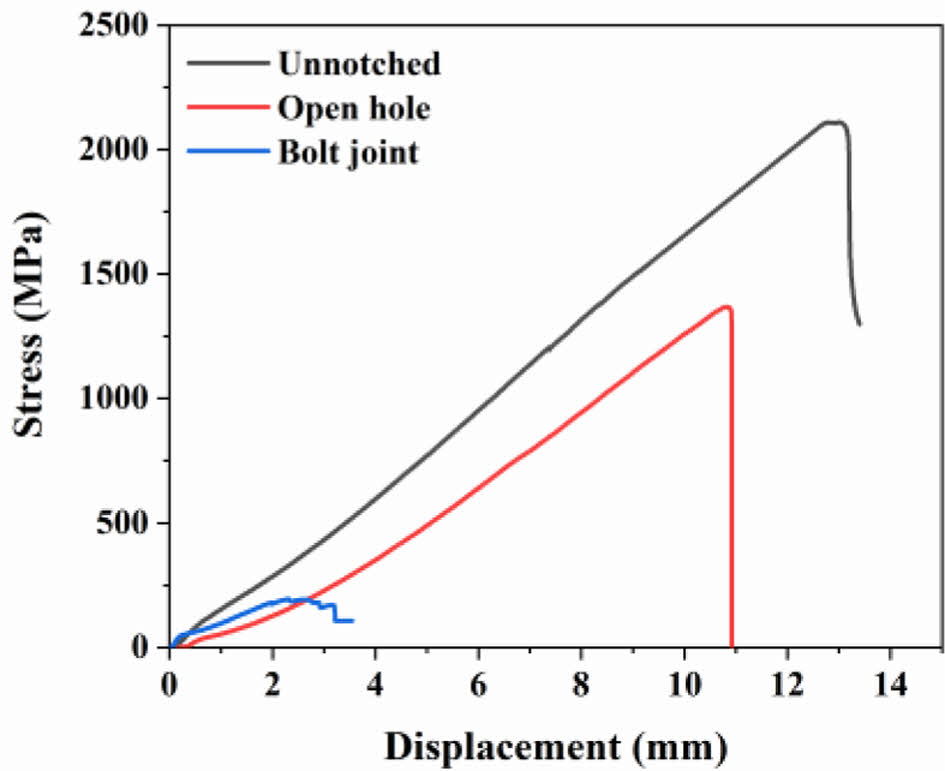

3.2 Comparison of Open Hole Tensile (OHT) and Bolt Joint Tensile(BJT) Properties of the CF/epoxy

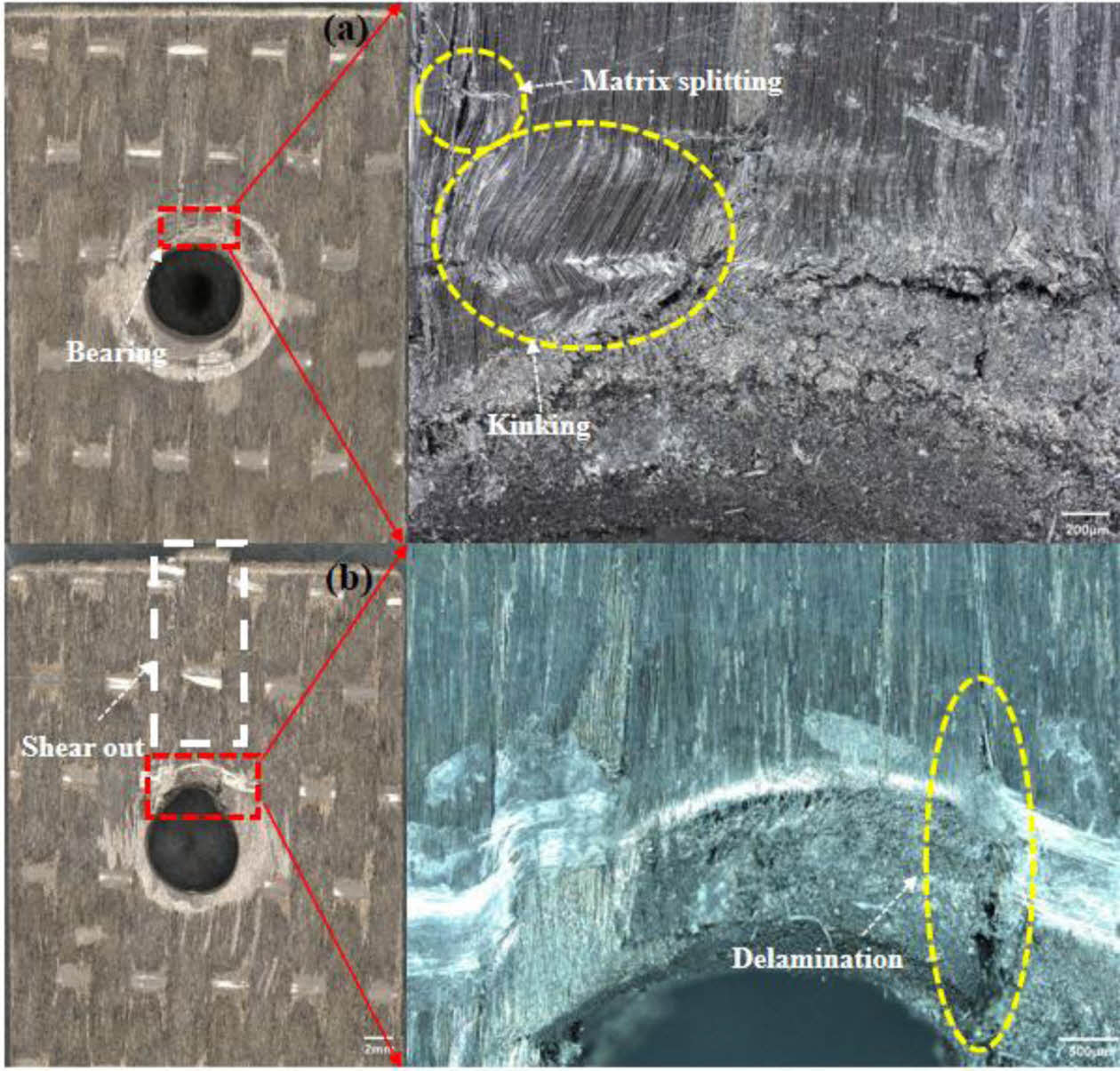

Fig. 4 illustrates the comparable stiffness between the Bolt Joint Tensile (BJT) and Open Hole Tensile (OHT) specimens, as expected due to the absence of bolt rotation and secondary bending in the joint displacement. The Open Hole Tensile (OHT) specimens exhibited a sharp drop in stress at the end of the linear portion, indicating an occurrence of unstable crack propagation, delamination, and catastrophic failure. In contrast, the BJT specimens experienced failure through shear out on the bolt side (as shown in Fig. 6b) and bearing failure on the nut side (as shown in Fig. 6a), involving fiber kinking, matrix splitting, and delamination. These combined failure modes contributed to the lower strength observed in the Bolt Joint Tensile (BJT) specimens compared to the Open Hole Tensile (OHT) specimens.

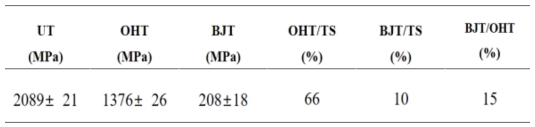

Notch strength retention is a critical design parameter in engineering applications. It is used as a normalized value for comparing the tensile strengths of samples with hole size, calculated from the TS (Tensile Strength) and Open Hole Tensile (OHT) values. The strength retention of the CF/epoxy composites, listed in Table 1, demonstrated a remarkable capability of withstanding tensile loads even in drilled conditions, with a strength retention value of 66%. The authors [14] proposed that delamination initiated at the hole's edge (as shown in Fig. 2) during testing leads to a reduction in the stress concentration factor (SCF) associated with the hole. However, when the hole is filled by a bolt, this relieving mechanism is suppressed (as shown in Fig. 6), resulting in lower strength for the Bolt Joint Tensile (BJT) specimens compared to the Open Hole Tensile (OHT) specimens. This leads to a bolt joint efficiency of 15%. These findings align with the study [15], which highlighted the significant reduction in strength for filled holes with tightened bolts due to fiber-matrix splitting and delamination, consistent with the observations in this study (as shown in Fig. 6). The explanation for the lower efficiency of bolted joints made with composites is in line with Hart Smith's well-known diagram [16]. The results presented in this paper conform to the general approximations of Hart-Smith's [16] bolted joint efficiency diagram. Fig. 5 Table 2

|

Fig. 2 Gross nominal and net nominal stress-strain curves CF/ epoxy composites |

|

Fig. 3 Stiffening phenomenon of open hole tensile specimen prior to the failure |

|

Fig. 4 Optical images showing the final failure of CF/epoxy composites a) full Open-hole tensile (OHT) specimens, b) hole edge area |

|

Fig. 5 Representing typical stress-displacement responses for open hole and bolt joint CF/epoxy |

|

Fig. 6 Optical images showing the final failure of CF/epoxy composites a) nut side, b) bolt side |

|

Table 2 Unnotched Tensile (UT), Open Hole Tensile (OHT), and Bolt Joint Tensile (BJT) for CF/epoxy composites |

This research focused on the tensile properties of carbon fiber/epoxy composites with open holes, as well as a comparison with bolt joint specimens. The following key observations were made:

1. The results Open Hole Tensile (OHT) showed that the gross nominal stress-strain curves of specimens initially followed the curve path of the net nominal stress-strain curves. However, at higher strain values, the curves started to deviate. This deviation was attributed to the increasing hole size, which led to higher net nominal modulus and strength compared to the gross nominal values. The failure in the open hole specimens primarily occurred at the hole edge, resulting in splitting failure of the matrix and subsequent fracture of the fibers.

2. It was observed that the stiffness of the Bolt Joint Tensile (BJT) specimens was similar to that of the Open Hole Tensile (OHT) specimens, as there was no bolt rotation causing secondary bending. However, the failure mechanisms differed between the two types of specimens. The bolt joint specimens experienced shear out failure on the bolt side and bearing failure on the nut side, contributed to lower strength in the Bolt Joint Tensile (BJT) specimens compared to the Open Hole Tensile (OHT) specimens.

3. The strength retention of the carbon fiber/epoxy composites with open holes was found to be 66%, indicating their excellent capability to withstand tensile loads even in drilled conditions. The bolt joint efficiency was calculated to be 15%, indicating a significant reduction in strength compared to the open hole specimens. The presence of a bolt in the hole suppressed the delamination and stress concentration relief mechanisms, leading to lower strength in the Bolt Joint Tensile (BJT) specimens.

4. Overall, the research highlighted the importance of considering stress concentration and failure mechanisms in composite materials with open holes and bolted joints. The findings provided valuable insights for materials selection and estimating the structural reliability of composite components in engineering applications.

This research was supported by Korea Institute for Advancement of Technology(KIAT) grant funded by the Korea Government(MOTIE) (P0008763, HRD Program for Industrial Innovation).

- 1. Holbery, J., and Houston, D., “Natural-fiber-reinforced Polymer Composites in Automotive Applications”, Jom, Vol. 58, 2006, pp. 80-86. https://doi.org/10.1007/s11837-006-0234-2.

-

- 2. Hua, Y., Yang, Y.-C., Yamanaka, A., and Ni, Q.-Q., “Low Friction Coefficient Property of Super Fiber-Reinforced Composites”, Advanced Composite Materials, Vol. 20, 2011, pp. 133-147. https://doi.org/10.1163/092430410X523953.

-

- 3. Kumar, S., Wu, C.M., Lai, W.Y., and Lin, P.C., “Pin Hole Tensile and Fatigue Properties of Self-reinforced PET Composites”, Composite Structures, Vol. 255, 2021, 112981. https://doi.org/10.1016/j.compstruct.2020.112981.

-

- 4. Kumar, S., Wu, C.M., Lin, P.C., Chen, J.C., and Shimamura, Y., “Strain Concentration of Double-edge Hole Ductile Composites in the Full Range of Deformation by Digital Image Correlation”, Express Polymer Letters,Vol. 16, 2022, pp. 1038-1051. https://doi.org/10.3144/expresspolymlett.2022.76.

-

- 5. Hwang, D.W., Kumar, S., Park, S.J., Shin, D.H., and Kim, Y.H., “Evaluation of the Bending Strength of Preloaded CF/PEKK at High Temperature”, Modern Physics Letters B, Vol. 37, No. 18, 2023, 2340028.

-

- 6. Li, X., Yu, T., Park, S.J., and Kim, Y.H., “Reinforcing Effects of Gypsum Composite with Basalt Fiber and Diatomite for Improvement of High-temperature Endurance”, Construction and Building Materials, Vol. 325, 2022, 126762.

-

- 7. Wu, C.M., Lin, P.C., Kumar, S., and Chen, J.C., “Long-term Open-hole Tensile Creep Properties of Self-reinforced PET Composites Measured by Digital Image Correlation,” Materials Chemistry and Physics, Vol. 278, 2022, 125633.

-

- 8. Aktaş, A., and Uzun, I., “Sea Water Effect on Pinned-joint Glass Fibre Composite Materials,” Composite Structures, Vol. 85, 2008, pp. 59-63. https://doi.org/10.1016/j.compstruct.2007.10.007

-

- 9. Wu, C.M., Kumar, S., Lin, P.C., and Chen, J.C., “Strain and Stress Concentration of Ductile Composites in Full-range Deformation by Digital Image Correlation,” Mechanics of Advanced Materials and Structures, Vol. 30, No. 18, 2023, pp. 3817-3825. https://doi.org/10.1080/15376494.2022.2084192.

-

- 10. Ahmad, H., Crocombe, A.D., and Smith, P.A., “Strength Prediction in CFRP Woven Laminate Bolted Single-lap Joints under Quasi-static Loading Using XFEM”, Composites Part A: Applied Science and Manufacturing, Vol. 66, 2014, pp. 82-93. https://doi.org/10.1016/j.compositesa.2014.07.013.

-

- 11. Hallett, S.R., Green, B.G., Jiang, W.G., and Wisnom, M.R., “An Experimental and Numerical Investigation into the Damage Mechanisms in Notched Composites,” Composites Part A: Applied Science and Manufacturing, Vol. 40, 2009, pp. 613-624. https://doi.org/10.1016/j.compositesa.2009.02.021.

-

- 12. D. ASTM, 5766. Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates, 2011.

-

- 13. Gamdani, F., Boukhili, R., and Vadean, A., “Tensile Strength of Open-hole, Pin-loaded and Multi-bolted Single-lap Joints in Woven Composite Plates,” Materials & Design, Vol. 88, 2015, pp. 702-712.

-

- 14. Portanova, M.A., and Masters, J.E., Standard Methods for open Hole Tension Testing of Textile Composites, 1995.

- 15. Yan, Y., Wen, W.-D., Chang, F.-K., and Shyprykevich, P., “Experimental Study on Clamping Effects on the Tensile Strength of Composite Plates with a Bolt-filled Hole,” Composites Part A: Applied Science and Manufacturing, Vol. 30, 1999, pp. 1215-1229.

-

- 16. Hart-Smith, L.J., Bolted Joint Analyses for Composite Structures--Current Empirical Methods and Future Scientific Prospects, ASTM International, 2004.

- 17. Yudhanto, A., Watanabe, N., Iwahori, Y., and Hoshi, H., “The Effects of Stitch Orientation on the Tensile and open Hole Tension Properties of Carbon/epoxy Plain Weave Laminates,” Materials & Design, Vol. 35, 2012, pp. 563-571.

-

- 18. Wu, C.‐M., and Lai, W.‐Y., “Mechanical and open Hole Tensile Properties of Self‐reinforced PET Composites with Recycled PET Fiber Reinforcement,” Journal of Applied Polymer Science Vol. 133, No. 29, 2016.

-

This Article

This Article

-

2023; 36(4): 259-263

Published on Aug 31, 2023

- 10.7234/composres.2023.36.4.259

- Received on Jun 22, 2023

- Revised on Jul 6, 2023

- Accepted on Aug 2, 2023

Services

Services

- Abstract

1. introduction

2. experimental details

3. results and discussions

4. conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Yun-Hae Kim

-

* Dept. of Ocean Advanced Materials Convergence Engineering, Korea Maritime and Ocean University, Busan 49112, Korea

- E-mail: yunheak@kmou.ac.kr

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.