- Effect of Interface on the Properties of Polyamide 6/Carbon Nanotube Nanocomposites Prepared by In-situ Anionic Ring-opening Polymerization

Jin Hong Min*, Mongyoung Huh**, Seok Il Yun*†

* Department of Chemical Engineering and Materials Science, Sangmyung University, Seoul 03016, Korea

*† Department of Chemical Engineering and Materials Science, Sangmyung University, Seoul 03016, Korea

** Affiliation Korea Institute of Carbon Convergence Technology, Jeonju 54853, Korea

Multiwalled carbon nanotubes (MWCNTs) are covalently

functionalized with isocyanates by directly reacting commercial hydroxyl

functionalized MWCNTs with excess 4,4'-methylenebis (phenyl isocyanate) (MDI)

and hexamethylene diiosocyanate (HDI). HDI-modified MWCNTs results in a higher

surface isocyanate density than MDI-modified MWCNTs. Anionic ring-opening

polymerization of e-caprolactam is conducted

using a sodium caprolactam initiator in combination with a di-functional

hexamethylene-1,6-dicarbamoylcaprolactam activator in the presence of

isocyanate functionalized MWCNTs. This polymerization proceeds in a highly

efficient manner at relatively low reaction temperature (150oC) and short reaction times (10

min). During the polymerization, the isocyanate functionalized MWCNTs act not

only as reinforcing fillers but also as second activators. Nanocomposites with

HDI modified MWCNTs exhibit higher reinforcement and faster isothermal

crystallization than MDI modified MWCNTs. The results show that PA6 chains grow

more effectively from HDI modified MWCNT surface than from MDI modified MWCNT

surface, resulting in stronger interaction between PA6 and MWCNTs.

Keywords: PA6, MWCNT, Isocyanate, Nanocomposite, Anionic ring-opening polymerization

Polyamide

6 (PA6) is one of the most widely used engineering plastics due to its superior

mechanical and thermal properties, oil resistance, low cost and ease of

synthesis [1-3]. These characteristics have usually been utilized to

produce filler reinforced PA6 composites in many high-end fields [4,5]. The high melting

temperature and viscosity of thermoplastics limits their growth in polymer

composites, mainly due to expensive and time-consuming manufacturing processes

such as autoclaves or hot presses. Significant reduction in matrix viscosity is

important for cost effective production of thermoplastic composites with

optimum impregnation of the reinforcements by the matrix. This can be achieved

by the reactive processing (or monomer casting) techniques, where the

thermoplastic matrices are synthesized in situ, through polymerization of

low-viscosity monomers or oligomers in the presence of the reinforcements [6-10]. The most commonly

used polymerization types is the ring-opening polymerization of e-caprolactam (ECL). In this mechanism, ring-shaped monomer

molecules are opened and transformed into high molecular weight PA6 without

liberation of by-products by means of an activator and a catalyst. The process

is carried in a way that the ECL polymerization and PA6 crystallization occur

simultaneously at temperatures 40-60oC lower than the melting point

of the resulting PA6 (220oC). This significantly reduces the overall

production cycle time and increases the energy efficiency of the process.

Despite CNTs having desirable physical properties, the full potential of

employing carbon nanotubes (CNTs) as reinforcements has been severely limited

because of the poor dispersion and poor interfacial bonding of CNTs to monomer

or polymer matrices. These problems largely stem from the smooth surface of

CNTs, which is chemically inert and incompatible with most solvents and

polymers [11-13]. Recently, the functionalization of CNTs with PA6

by using the grafting-from strategy has been adopted to improve the dispersion

and interfacial bonding of CNTs in PA6 matrix [14,15]. Utilizing

di-isocyanate as a surface modifier for hydroxyl functionalized CNT and

subsequent CNT surface initiated anionic polymerization of ECL have been a

facile route to PA6 functionalization of CNTs [14,15]. In the present

study, we used two different modifiers, 4,4'-methylenebis (phenyl isocyanate)

(MDI) and hexamethylene diiosocyanate (HDI) to incorporate isocyanate

functionalities onto the surface of MWCNTs. Anionic ring-opening polymerization

of ECL was conducted in the presence of MDI and HDI modified MWCNTs by using a

sodium caprolactam (C10) initiator in combination with a di-functional

hexamethylene-1,6-dicarbamoylcaprolactam (C20) activator. In this case, the PA6

chain grows from the MWCNT surface, while C10/C20 initiate polymerize in the bulk

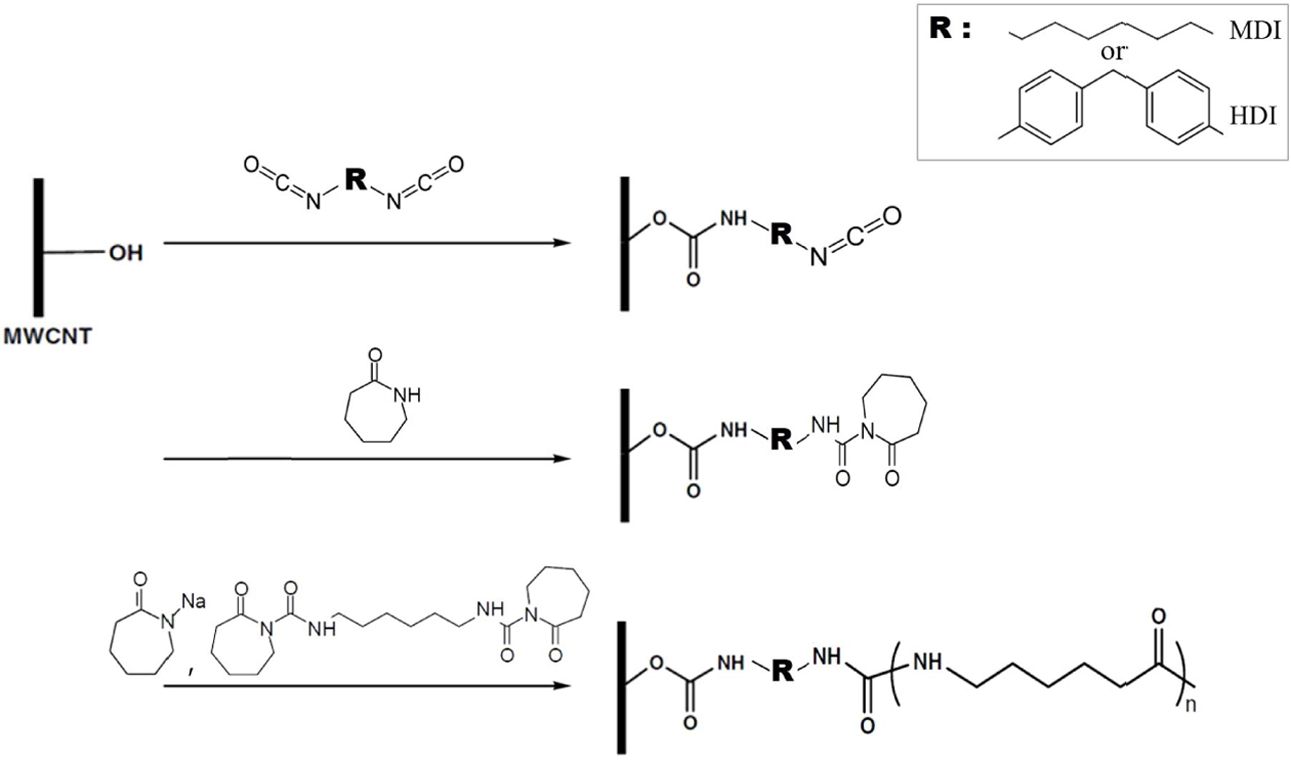

ECL melt as shown in Fig.

1. To date, no direct comparison between MDI and HDI for preparing

isocyanate functionalized CNTs has been reported in the literature. In this

study, compared to unmodified CNTs, the isocyanate functionalized CNTs,

especially HDI modified CNTS, more effectively reinforced the nanocomposites

and accelerate PA6 isothermal crystallization

|

Fig. 1 Synthesis of isocyanate functionalized MWCNTs and subsequent PA6 chain growth from functionalized MWCNTs |

2.1

Materials

The

ECL used was an anionic polymerization grade (AP-Nylon¢ç grade) supplied by

Bruggemann Chemical (Heilbronn, Germany) as it has a low moisture content

(<100 ppm). The MDI, HDI, dibutyltin dilaurate (DBDL) and anhydrous

tetrahydrofuran (THF) were purchased from Sigma-Aldrich (US). A C20 as an

activator and a C10 initiator were purchased from Brueggemann Chemical. MWNTs-OH

(3.06 wt% OH) was purchased from US Research Nanomaterials, Inc (purity >

95%, diameter 10-20 nm, length 10-30 mm).

2.2

Surface modification of hydroxyl functionalized MWCNTs

The

CNT-OH (2 g) in anhydrous THF (100 mL) was sonicated for 20 min to obtain a

homogeneous suspension of CNT-OH, and was then put into a 100 mL three-necked

round-bottom flask. After a mechanical stirring under nitrogen (N2),

the mixture was heated to 50oC, followed by addition of 500 mol% MDI

(or HDI) relative to CNT-OH and 1.25 mL DBDL catalyst. The reaction was

maintained at 50oC for 1 h and filtered and dried.

2.3

In-situ synthesis of PA6/MWNTs Nanocomposite

ECL

monomers (100 g) were put into a three-necked flask and heated to 80°C under a

nitrogen atmosphere. After the monomer was melted, MDI (or HDI) modified MWCNTs

(0-1 wt%) were added. The mixed melt was stirred and sonicated for another 20

min. The C10 (2.5 wt%) and C20 (1.67 wt%) were added to the mixed melt then

immediately cast into a mold at 150°C and reacted for 10 min; thus, the product

of PA6 nanocomposite was obtained.

2.4

Characterization

Nanocomposite

samples were cut into thin flakes and weighed. The samples were refluxed for 24

h to remove unreacted ECL monomer in hot distilled water (95oC).

After drying, samples were weighed again. The sample weight difference was used

as 100 × (weight after refluxing / weight before refluxing) to obtain a degree

of conversion (wt%). Fourier transform infrared (FT-IR) spectra were obtained

by use of a Bruker/Tensor27 spectrometer (Germany). The spectrum of samples on

the ATR plate was collected at a 4 cm-1 resolution with 2 min

intervals by co-adding 16 scans. The isothermal crystallization of PA6 and PA6

nanocomposites was studied by differential scanning calorimetric (DSC) analysis

with a modulated DSC (Q200, TA instruments, US). The samples of about 10 mg

were heated quickly from ambient temperature to 250oC under nitrogen

atmosphere, and then held for 5 min to eliminate the effect of the previous

thermal history. Then the samples were quenched to isothermal crystallization

temperature (188, 190, and 192oC), and the isothermal

crystallization was carried out at these temperatures

The

MWCNT-OH material was reacted with MDI and HDI to produce isocyanate

functionalized MWCNTs (Fig. 1).

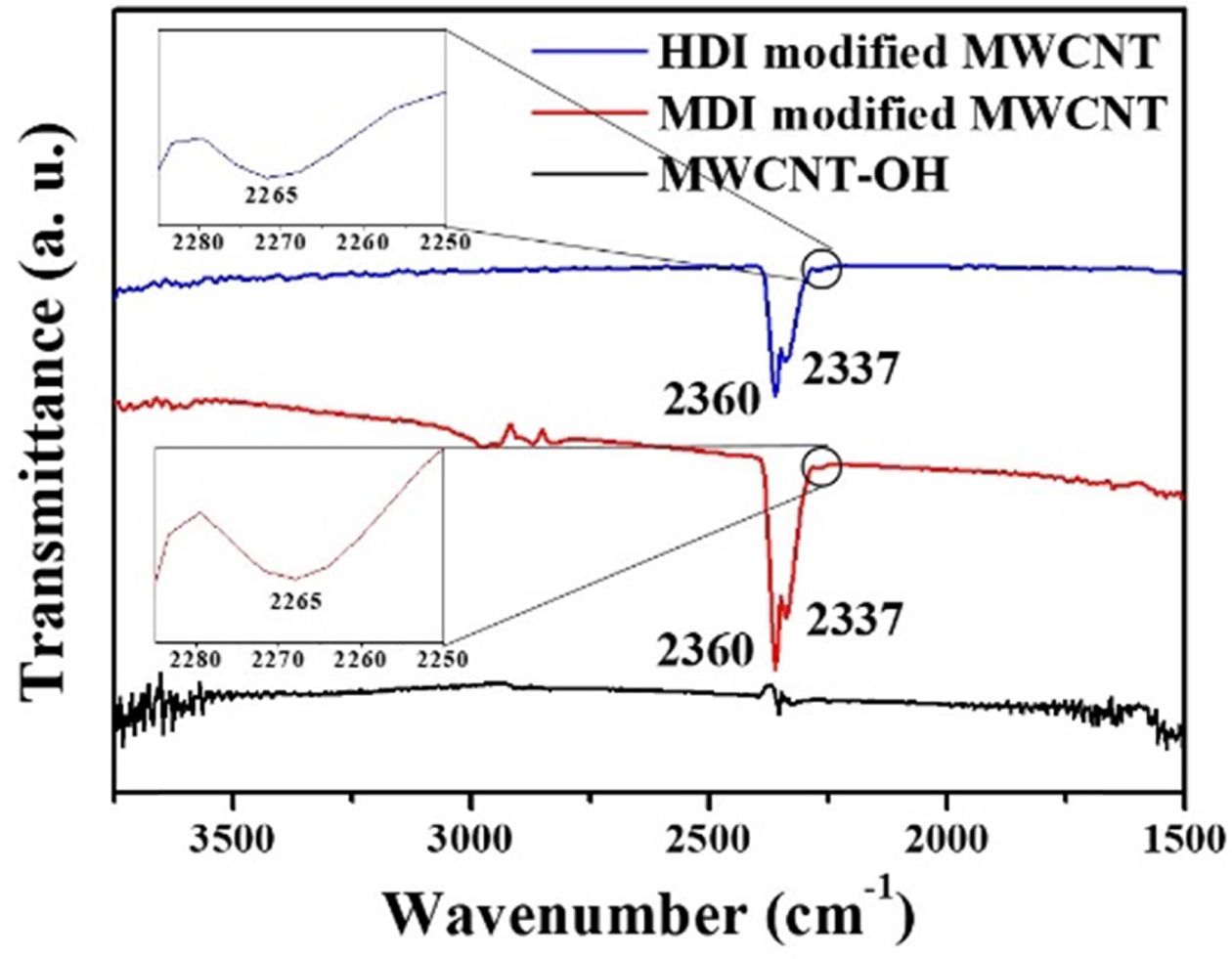

Fig.

2 shows the FTIR spectra of MWCNT-OH, isocyanate functionalized MWCNTs by

MDI and HDI. Unlike the MWCNT-OH, addition of excess TDI and MDI to the

MWCNT-OH, resulted in the appearance of clearly discernable bands at 2360 and

2337 cm-1 corresponding to C=O bond and asymmetric stretching of the

appended terminal isocyanate groups, respectively [16]. The typical band

at 2265 for isocyanate group was also observed [14,15]. The results

indicate that the isocyanates were successfully incorporated into the surface

of MWCNT-OH using the coupling agents, HDI and MDI. To gain a more quantitative

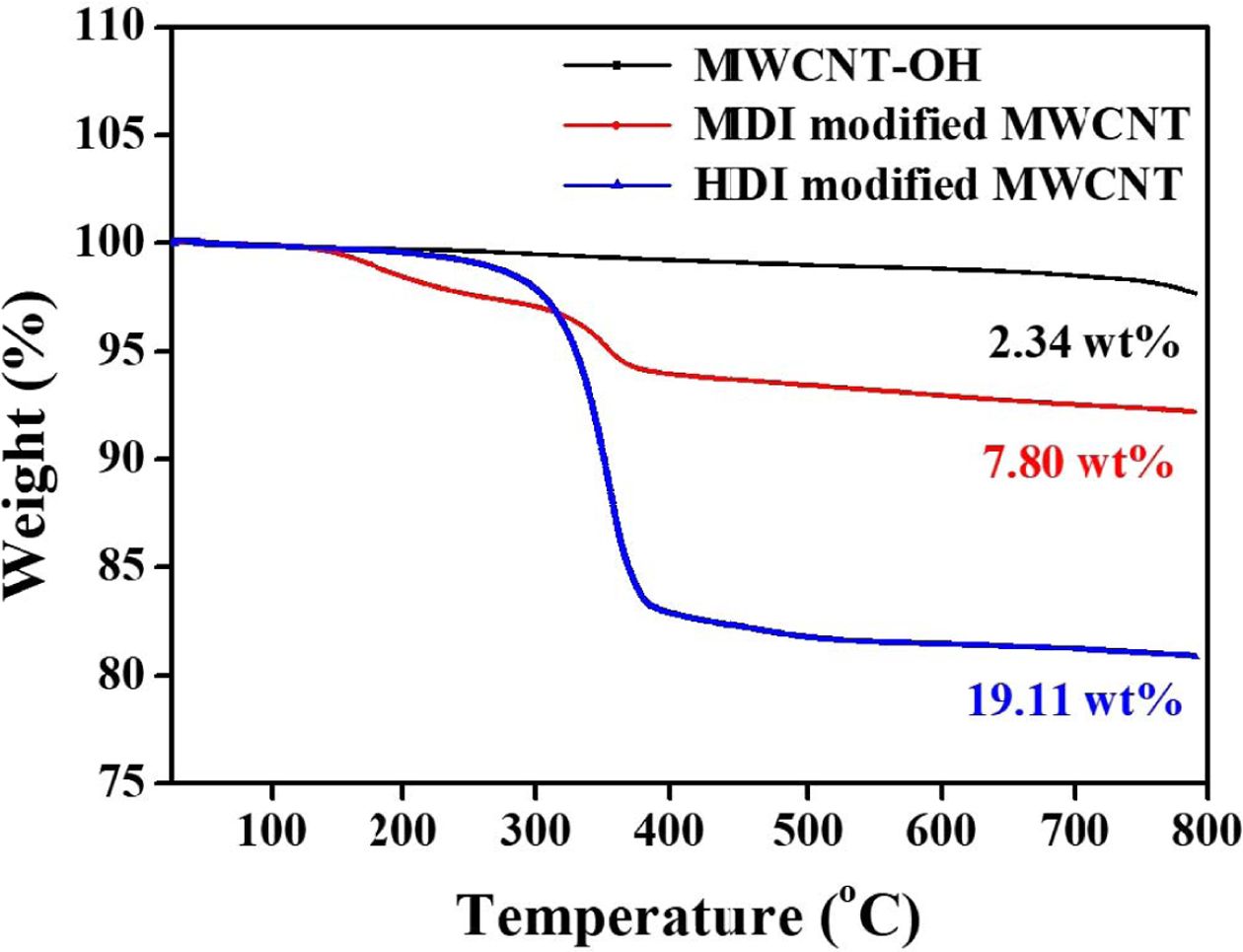

picture of the extent of nanotube functionalization, TGA analysis was performed

on the surface functionalized MWCNTs as depicted in Fig. 3. For comparison,

the TGA plot of MWCNT-OH showed a gradual mass loss of around 2.34 wt% as the

temperature reaches 800oC. There is a distinct difference in mass

loss region between 300 and 400oC for different isocyanate functionalized

MWCNTs. HDI modified MWCNTs showed much greater loss than MDI modified MWNTs.

The mass loss was found to be 7.80 and 19.11 wt%, for the MDI and HDI modified

MWCNT, respectively. Considering that the starting nanotubes have a hydroxyl

group concentration of 3.06 wt%, the TGA results indicate that about 55.4% of

the available hydroxyl groups reacted with HDI despite the poor solubility of

MWCNTs in THF. However, for MDI modified MWNTs, only a 12.% of available OH

groups reacted with MDI.

In

the presence of isocyanate functionalized MWCNTs, anionic ring-opening

polymerization of ECL was conducted by using a C10 initiator in combination

with a C20 activator. Isocyanate groups of MDI and HDI modified MWCNTs could

serve as activators of ECL during the in situ polymerization. In this case,

Polymerization occurs from the MWCT surfaces and in bulk ECL melts by C10,

simultaneously. Modified or unmodified MWCNTs were found to be well dispersed

in the molten ECL by visual inspection. The molten ECL and final composite

containing MWCNTs showed no difference with respect to CNT dispersion by CNT

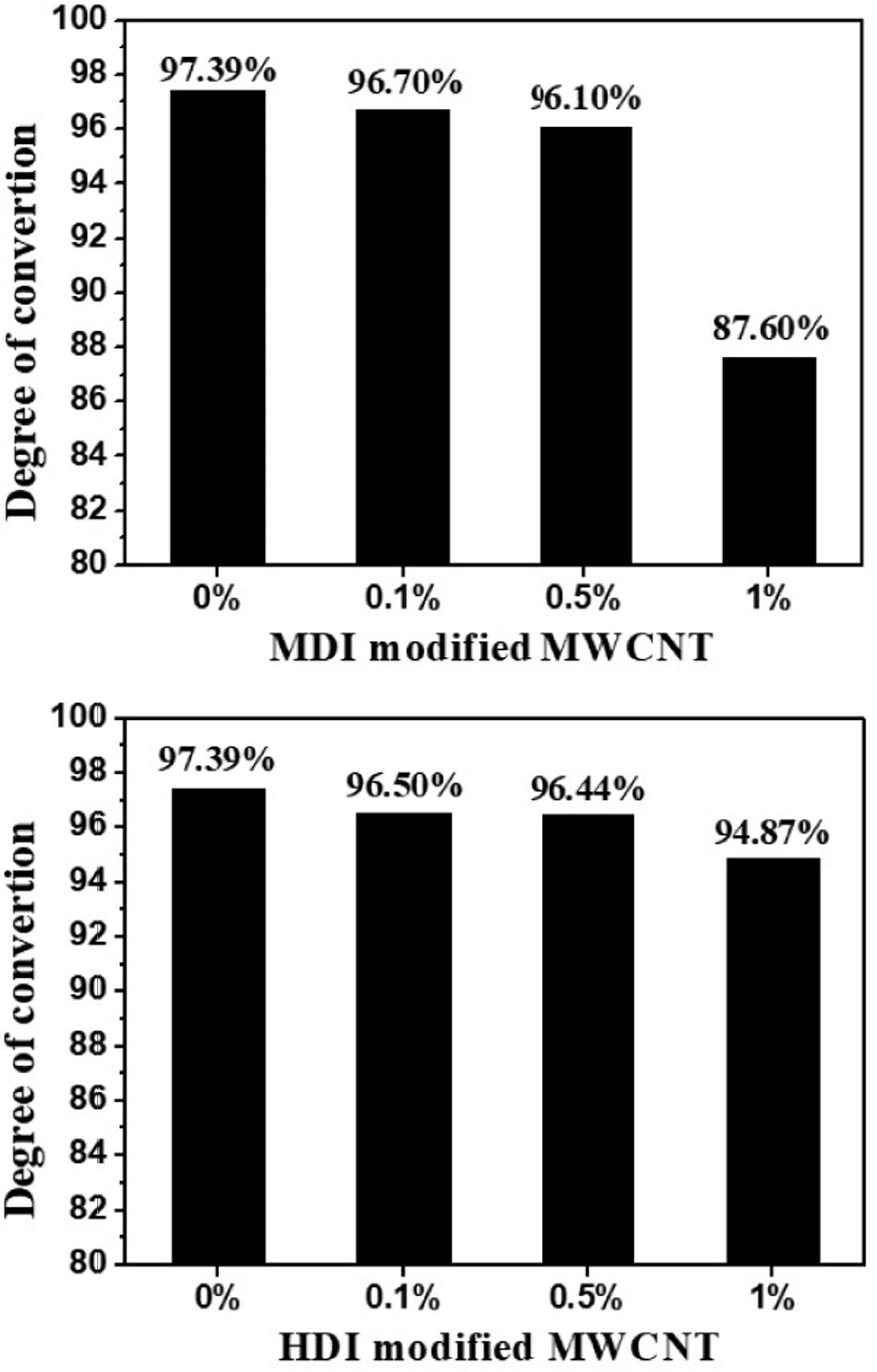

surface modification [17]. The effects of the MWCNT concentration on the degree of

conversion are presented in Fig. 4. The final degree of conversion showed the downward

trend with increasing MWCNT concentration. According to the TGA results, compared to

HDI modified MWCNTs, MDI modified MWCNTs contain more unreacted OH

functionalities that can terminate the anionic ring-opening polymerization,

resulting in the greater reduction in conversion for nanocomposites.

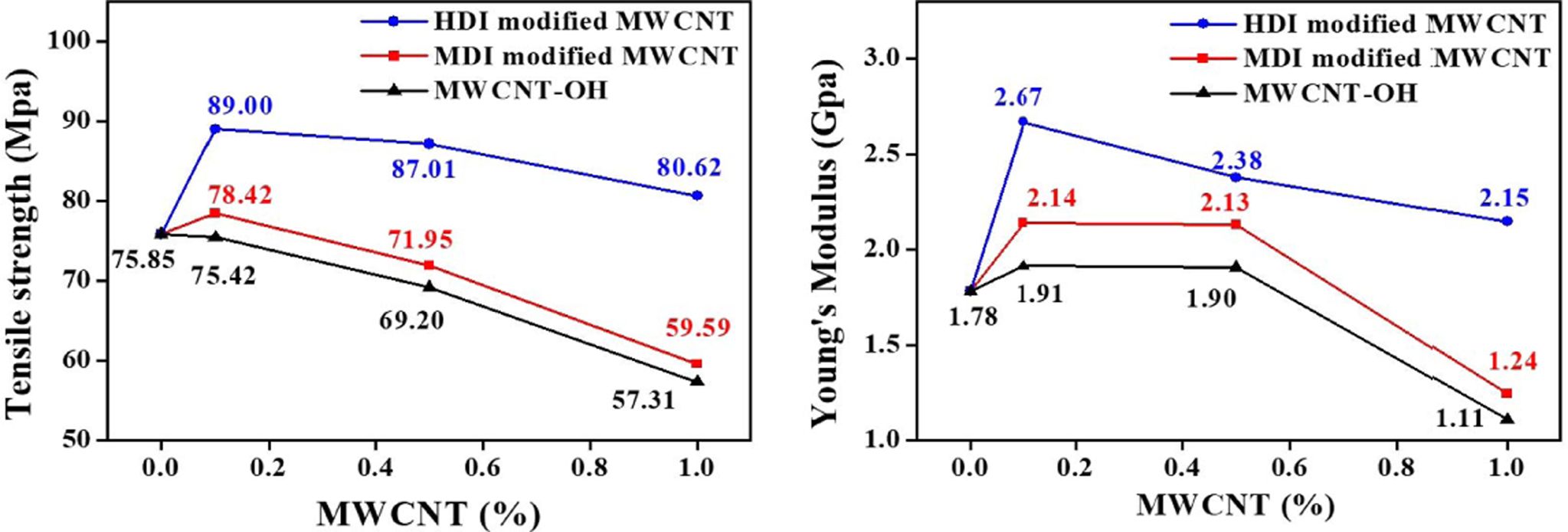

The

tensile test results of neat PA6 and PA6/MWCNTs nanocomposites with different

CNT loadings are summarized in Fig. 5. Nanocomposites with HDI-modified CNTs showed higher

mechanical improvement than MDI-modified CNTs and hydroxyl CNTs. The results

clearly displayed that higher isocyanate density on the CNT surface led to

higher PA6 grafting density during the polymerization. High PA6 grafting

density of CNT resulted in stronger interactions and better compatibility

between PA6 and MWCNT which are responsible for higher mechanical reinforcement

of nanocomposite compared to lower isocyanate density on the CNT surface (MDI

modified MWCNT).

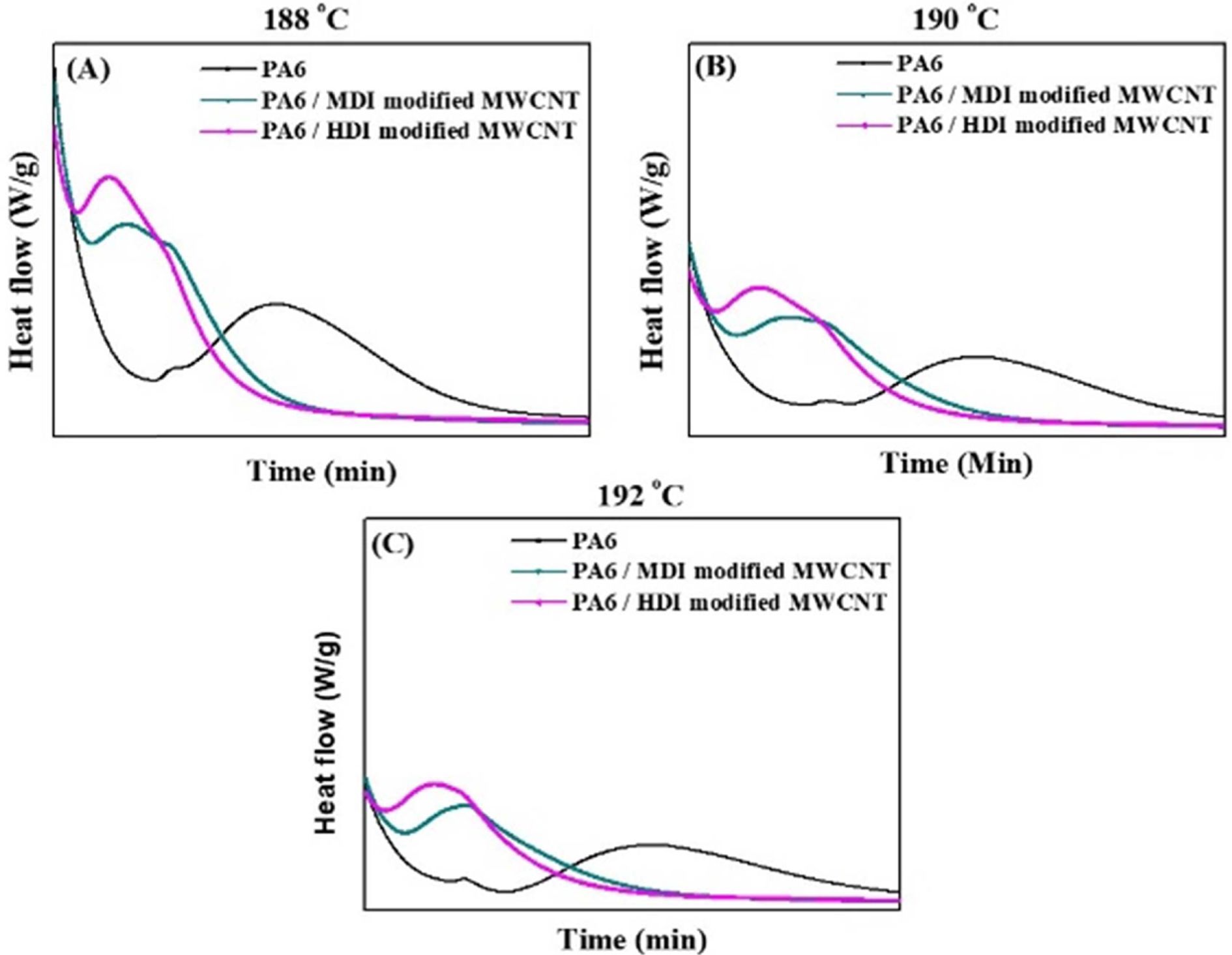

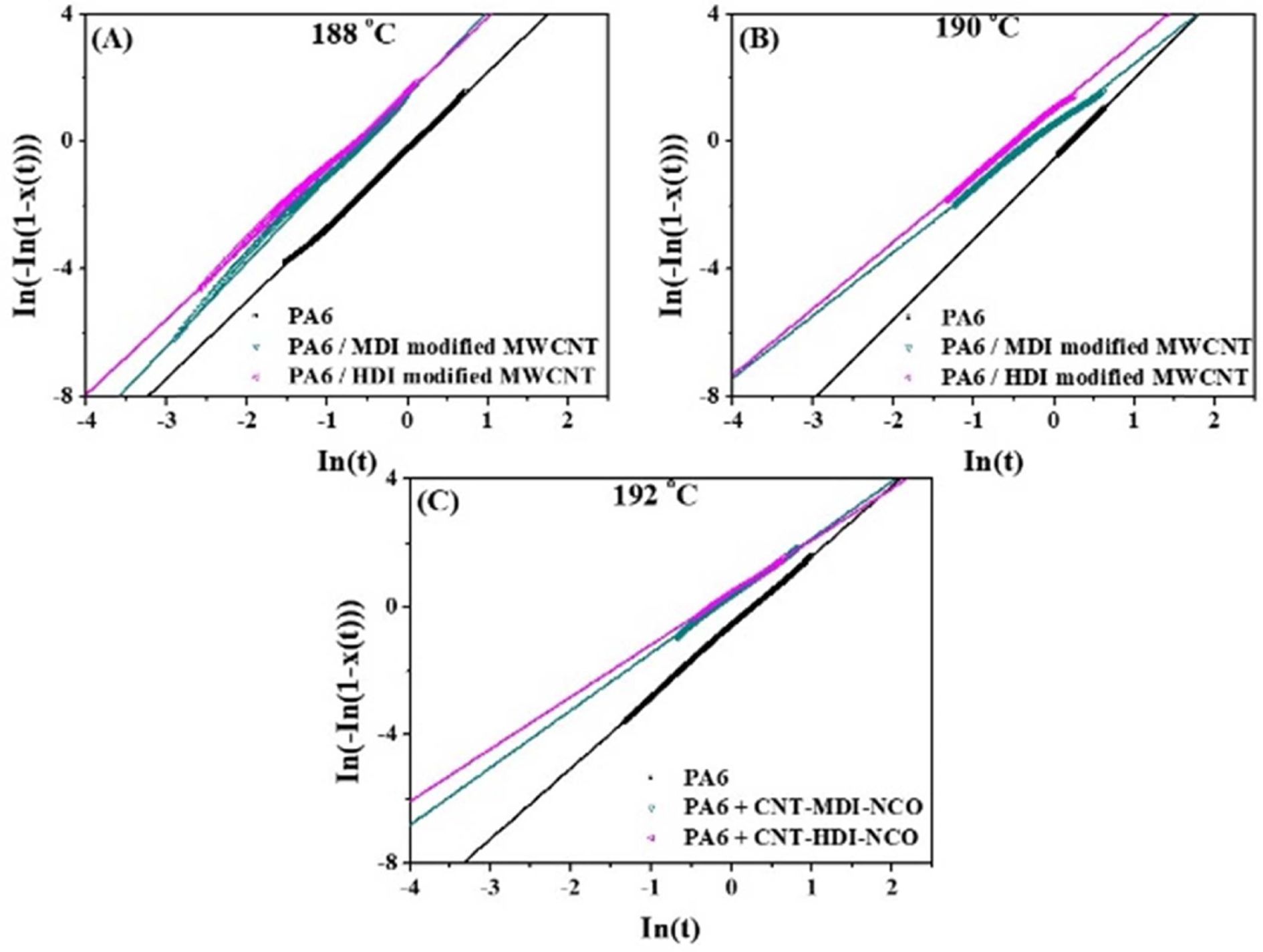

In

order to study the isothermal crystallization kinetics, the heat release during

the process was monitored. Fig. 6a-c shows the

characteristic isothermal crystallization exotherms of PA6 and PA6 nanocomposites containing surface

modified CNTs with CNT content of 0.1%. From the Fig. 6, the relative

degree of crystallinity, X(t) at time t, can be

established by

where the denominator is the total area under the isothermal

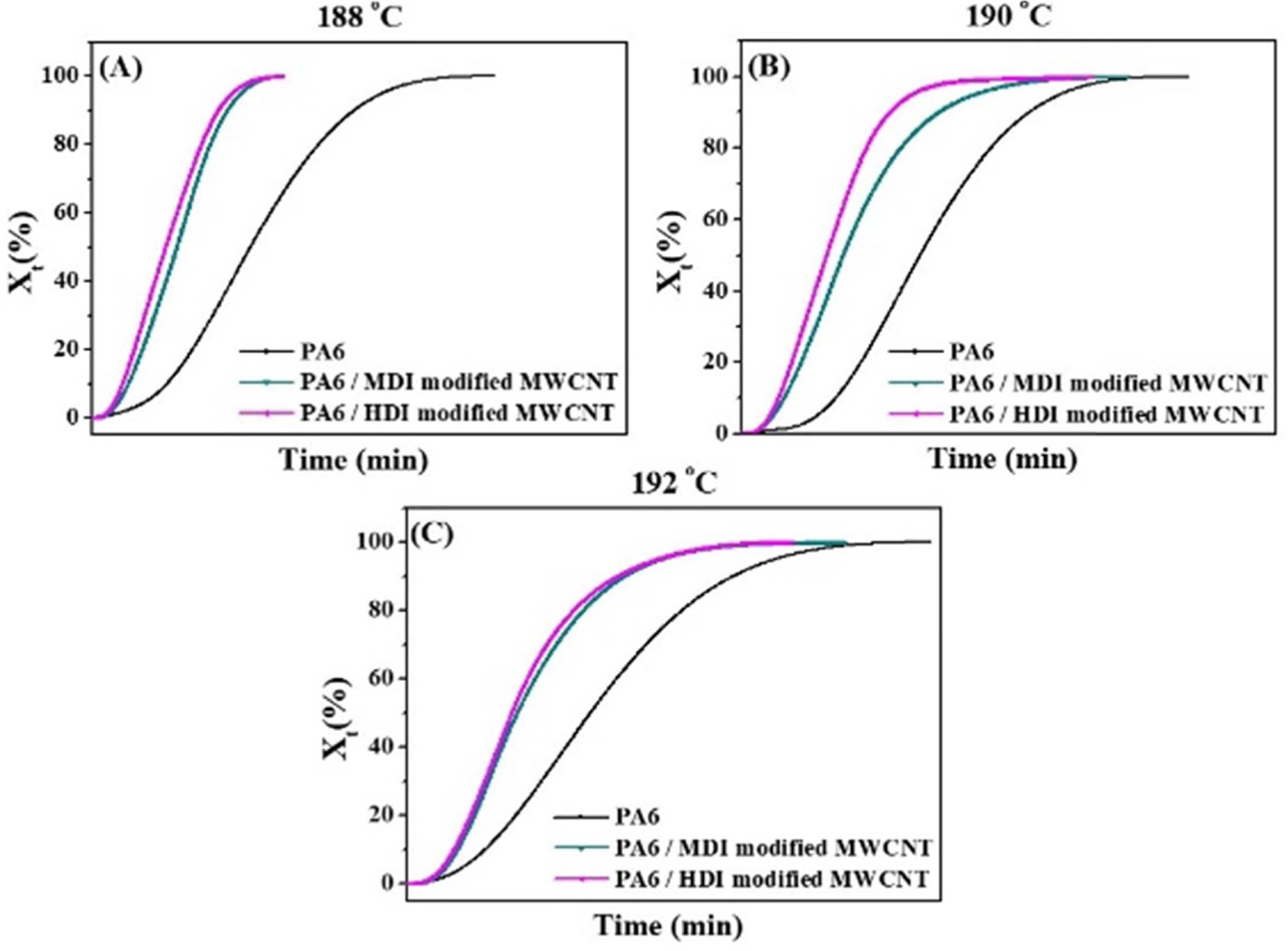

crystallization graph by DSC. Fig. 7 shows X(t) as a function of the

crystallization time t at different crystallization temperatures. A

typical sigmoidal evolution is seen in all three curves. From these Fig. 7, it can be

concluded that the addition of CNTs significantly shortened the corresponding

crystallization time of PA6. One of the most important rate parameter,

crystallization half-time (t0.5) which is defined as the time taken

the relative crystallinity of the sample reaches the value of 50% can be

directly obtained from Fig. 7.

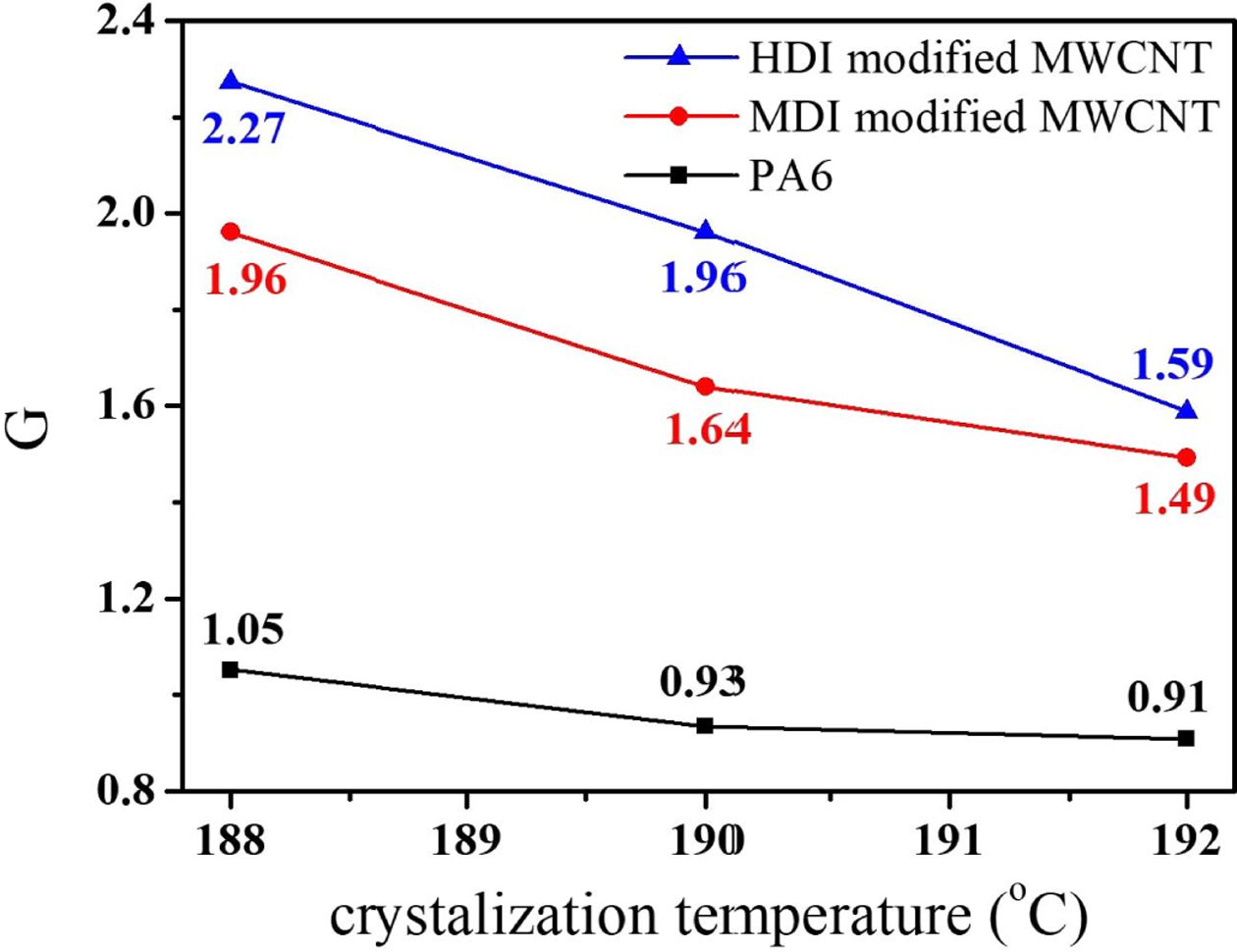

The

reciprocal (G) of t0.5 is usually used as the overall

crystallization rate and G values at different crystallization temperature of

188, 190, 192oC were summarized in Fig. 8. At all Tc,

the G value of the nanocomposites was greater than neat PA6 indicating that CNT

acted as a nucleating agent for PA6. Particularly, the HDI modified MWCNT

accelerated PA6 crystallization more efficiently than the MDI modified MWCNT.

The high surface PA6 density of CNTs may have resulted in stronger interfacial

interactions and compatibility of nanocomposite, than the low PA6 density of

CNT surfaces. The enhanced compatibility and interfacial interactions between

filler and matrices generally accelerates the nucleation of crystallization

very effectively. In addition, for all the samples the G value increased with Tc,

in agreement with the kinetics theory of crystallization, which expects for

crystallization close to the melting temperature, a decrease of undercooling

will slow the crystallization with increasing Tc. The isothermal

melt crystallization kinetics of the samples was further analyzed by the

well-known Avrami equation, which assumes the relative degree of crystallinity

(Xt) develops with crystallization time (t) as follows [18]:

or

where n is Avrami exponent which depends on the mechanism of nucleation

and growth of the crystal and k is the overall crystallization rate

constant. Plotting ln[-ln(1 - X(t)]

versus ln t therefore yields a straight line with a slope of n,

and the k value can be determined from the point of intersection with

the y axis.

Fig.

9 shows the linear relation between ln[-ln(1 - X(t)] and ln t for the samples at

various Tc. Table 1 summarizes the values of n and k for

neat PA6 and its nanocomposites crystallized at different Tc. The k

values for the nanocomposites found to be greater than those for neat PA6 and

nanocomposites with HDI-modified CNTs which is consistent with G values. As

anticipated the k values also decreased with increasing Tc.

The Avrami exponent (n) represents the dimensionality of the growth,

three-dimensional crystallization a theoretical value of 3 should be obtained

for n. The lower-than-3 n values in the table could be due to mixed 3D

and 2D crystallization. For Tc = 188oC, the n

values were found to be 2.4~2.7 and almost unchanged with the addition of CNTs,

suggesting that despite the CNT loading, the crystallization mechanism of PA6

remained unchanged. However, at the higher Tc = 190 and 192oC,

n values decreased to 2.21 for PA6. Compared to PA6, the n values

were dropped further to 1.63 for nanocomposites with increasing Tc.

The changes in Avrami exponent after the addition of MWCNTs indicate that the

presence of MWCNT modified the growth pattern of PA6 crystals. With X(t)

= 0.5, from eq. (3) the relation

between the half-time and the crystallization parameter k can be

expressed as

The

half-time can be directly determined from X(t) data (Fig. 7) or be calculated

using eq. (4). Usually, the

Avrami equation can fit data in the primary crystallization range Nevertheless

a comparison between the experimental and the theoretically predicted values of

the half-crystallization time also indicates that the fits are very good up to

50% conversion since the values are quite similar.

|

Fig. 2 FTIR spectra of the MWCNT-OH, MDI and HDI-modified MWCNT |

|

Fig. 3 TGA data for the MWCNT-OH, MDI and HDI-modified MWCNT |

|

Fig. 4 The effect of MWCNTs on the degree of conversion |

|

Fig. 5 Effect of MWCNT loading on the mechanical properties of PA6/MWCNT nanocomposites, (a) the tensile strength and (b) Young’s modulus |

|

Fig. 6 DSC thermograms (cooling scan) of PA6 and PA6/MWCNT nanocomposites at various Tc at (a) 188 (b) 190 and (c) 192oC |

|

Fig. 7 Effect of surface modification on the relative degree of crystallinity, X(t) at different Tc |

|

Fig. 8 The variation of G value (=1/t0.5) as a function of Tc for PA6 and PA6/MWCNT nanocomposites |

|

Fig. 9 The linear relation of ln[-ln(1 - X(t)] and ln t for PA6 and PA6/MWCNT nanocomposites at various Tc at (a) 188 (b) 190 and (c) 192oC |

|

Table 1 Isothermal melt crystallization kinetic parameters for PA6 and MWCNT nanocomposites |

a Determined from Fig. 7 |

The

isocyanate functionalized MWCNTs was prepared by directly reacting commercial

hydroxyl functionalized MWCNTs with excess MDI and HDI. HDI-modified MWCNTs

resulted in the CNTs with higher isocyanate density than MDI-modified MWCNTs.

Anionic ring-opening polymerization of ECL was conducted by using a C10

initiator in combination with a C20 activator in the presence of isocyanate

functionalized CNTs as the second activator and reinforcing filler. This

polymerization proceeded in a highly efficient manner at relatively low

reaction temperature (150oC) and short reaction times (10 min). The

isocyanate functionalized CNTs improved nanocomposites more effectively than

hydroxyl functionalized CNTs. The results indicate that PA6 was successfully

grown from the MWCNT surface during the polymerization in the e-caprolactam melt. Nanocomposites with HDI modified MWCNTs

showed higher reinforcement and faster isothermal crystallization than MDI

modified MWCNTs. The results showed that PA6 chains grew more effectively from

HDI modified MWCNTs than from MDI modified MWCNTs, resulting in stronger

interaction between PA6 and MWCNT surface.

For

financial support of this research, we thank the core technology development

program (10052724) funded by the Ministry of Trade, Industry & Energy

(Republic of Korea).

- 1. Marchildon, K., “Polyamides - Still Strong After Seventy Years,” Macromolecular Reaction Engineering, Vol. 5, 2011, pp. 22-54.

-

- 2. Pervaiz, M., Faruq, M., Jawaid, M., and Sain, M., “Polyamides: Developments and Applications Towards Next-Generation Engineered Plastics,” Current Organic Synthesis, Vol. 14, 2017, pp. 146-155.

-

- 3. Winnacker, M., “Polyamides and Their Functionalization: Recent Concepts for Their Applications as Biomaterials,” Biomaterial Science, Vol. 5, 2017, pp. 1230-1235.

-

- 4. Feldman, D., “Polyamide Nanocomposites,” Journal of Macromolecular Science, Part A-Pure and Applied Chemistry, Vol. 54, 2017, pp. 255-262.

-

- 5. Faridirad, F., Ahmadi, S., and Barmar, M., “Polyamide/Carbon Nanoparticles Nanocomposites: A Review”, Polymer Engineering and Science, Vol. 57, 2017, pp. 475-494.

-

- 6. van Rijswijk, K., Teuwen, J.J.E., Bersee, H.E.N., and Beukers, A., “Textile Fiber-reinforced Anionic Polyamide-6 Composites. Part I: The Vacuum Infusion Process”, Composites Part A-Applied Science and Manufacturing, Vol. 40, 2009, pp. 1-10.

-

- 7. van Rijswijk, K., van Geenen, A.A., and Bersee, H.E.N., “Textile Fiber-reinforced Anionic Polyamide-6 Composites. Part II: Investigation on Interfacial Bond Formation by Short Beam Shear Test”, Composites Part A-Applied Science and Manufacturing. Vol. 40, 2009, pp. 1033-1043.

-

- 8. Barhoumi, N., Maazouz, A., Jaziri, M., and Abdelhedi, R., “Polyamide from Lactams by Reactive Rotational Molding via Anionic Ring-opening Polymerization; Optimization of Processing Parameters”, Express Polymer Letters, Vol. 7, 2013, pp. 76-87.

-

- 9. Vicard, C., De Almeida, O., Cantarel, A., and Bernhart, G., “Experimental Study of Polymerization and Crystallization Kinetics of Polyamide 6 Obtained by Anionic Ring Opening Polymerization of Epsilon-caprolactam”, Polymer, Vol. 132, 2017, pp. 88-97.

-

- 10. Maazouz, A., Lamnawar, K., and Dkier, M., “Chemorheological Study and In-situ Monitoring of PA6 Anionic-ring Polymerization for RTM Processing Control”, Composites Part A-Applied Science and Manufacturing, Vol. 107, 2018, pp. 235-247.

-

- 11. Ajayan P.M., and Tour, J.M., “Nanotube Composites”, Nature, Vol. 447, 2007, pp. 1066-1068.

-

- 12. Sahoo, N.G., Rana, S., Cho, J.W., Li, L., and Chan, S.H., “Polymer Nanocomposites Based on Functionalized Carbon Nanotubes”, Progress in Polymer Science, Vol. 35, 2010, pp. 837-867.

-

- 13. Spitalsky, Z., Tasis, D., Papagelis, K., and Galiotis, C., “Carbon Nanotube-polymer Composites: Chemistry, Processing, Mechanical and Electrical Properties”, Progress in Polymer Science Sci., Vol. 35, 2010, pp. 357-401.

-

- 14. Yang, M., Gao, Y., Li, H., and Adronov, A., “Functionalization of Multiwalled Carbon Nanotubes with Polyamide 6 by Anionic Ring-opening Polymerization”, Carbon, Vol. 45, 2007, pp. 2327-2333.

-

- 15. Yan, D., and Yang, G., “Synthesis and Properties of Homogeneously Dispersed Polyamide 6/MWNTs Nanocomposites via Simultaneous in situ Anionic Ring‐opening Polymerization and Compatibilization”, Journal of Applied Polymer Science, Vol. 112, 2009, pp. 3620-3626.

-

- 16. Oumi, L., Mirzaei, M., Ashtari, P., Ramazani, A., Rahimi, M., and Bolourinovin, F., “Isocyanate Functionalized Multiwalled Carbon Nanotubes for Separation of Lead from Cyclotron Production of thallium-201”, Journal of Radioanalytical and Nuclear Chemistry, Vol. 310, 2016, pp. 633-643.

-

- 17. Bernat, P., Hladka, O., Fismanova, M., Roda, J., and Brozek, J., “Polymerization of Lactams. 98: Influence of Water on Thenon-activated Polymerization -caprolactam”, European Polymer Journal, Vol. 44, 2008, pp. 32-41.

-

- 18. Avrami, M., “Granulation, Phase Change, and Microstructure Kinetics of Phase Change. III”, The Journal of Chemical Physics, Vol. 9, 1941, pp. 177-183.

-

This Article

This Article

-

2019; 32(6): 375-381

Published on Dec 31, 2019

- 10.7234/composres.2019.32.6.375

- Received on Oct 9, 2019

- Revised on Oct 31, 2019

- Accepted on Dec 9, 2019

Services

Services

- Abstract

1. introduction

2. experimental

3. results and discussion

4. conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Seok Il Yun

-

Department of Chemical Engineering and Materials Science, Sangmyung University, Seoul 03016, Korea

- E-mail: yunsans@smu.ac.kr

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.

Copyright ⓒ The Korean Society for Composite Materials. All rights reserved.